Ordering Extra Components for PCB Assembly – A Small Cost That Saves Big Headaches

Introduction

When ordering printed circuit boards (PCBs) from a subcontractor, it’s tempting to purchase only the exact number of components needed for the assembly. After all, why spend more on extra parts that may not even be used?

However, this approach often backfires. Small, seemingly insignificant component shortages can bring production to a halt, delaying the entire project. In particular, passive components like resistors and capacitors are frequently lost during setup, and without extras on hand, not all circuit boards can be completed.

In this article, we’ll explain why ordering extra components is essential, how much to order, and how a little foresight can prevent major manufacturing headaches.

Why Extra Components Matter

1. Setup Wastage in SMT Machines

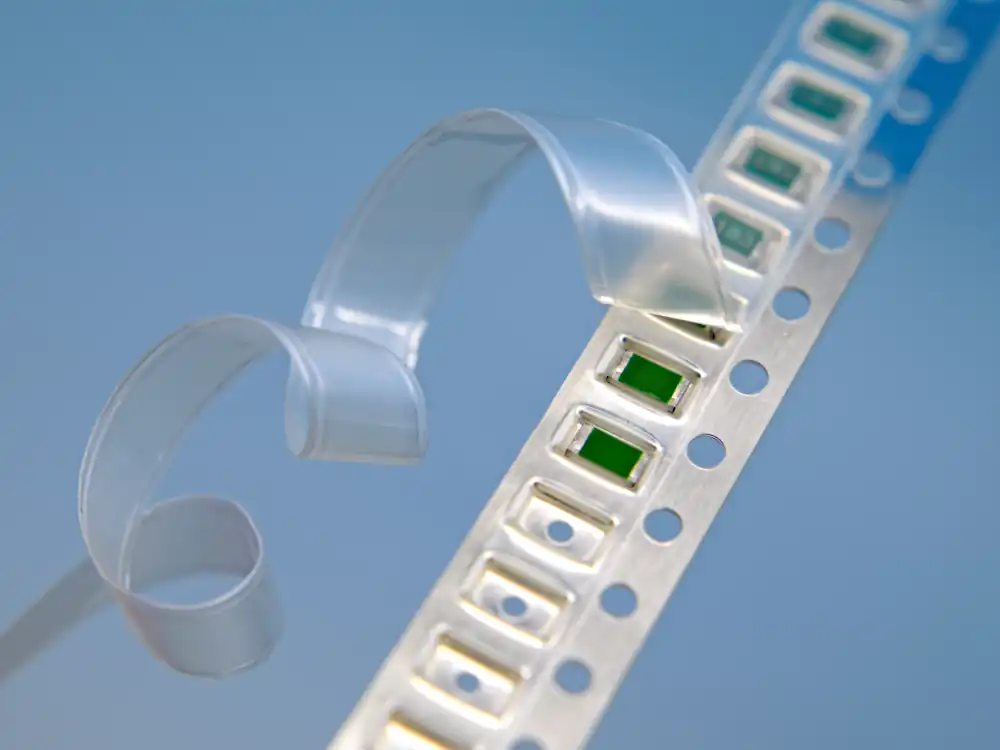

Modern PCB assembly relies on automated pick-and-place machines to position components onto the board with precision. However, every time a machine is programmed for a new job, some components are lost during the setup phase. This is because:

- The first few components are often used for calibration. Usually, the measured component can be returned to the tape, but sometimes it cannot.

- Feeders require a lead-in strip of components to function properly, and there is a high possibility of component loss during pick-and-place machine feeder setup.

- Some components may misfeed or be rejected by component measurement systems.

Without extra components available, a subcontractor may find themselves unable to complete every board in the batch.

2. Handling and Process Losses

Beyond machine setup, additional losses can occur due to:

- Manual handling: Small components can be easily dropped or damaged during loading.

- Reflow soldering: Components might shift, tombstone, or be soldered incorrectly, requiring rework or replacement.

- Process variations: Even in a well-controlled manufacturing environment, occasional component loss is inevitable.

A small buffer of extra components ensures that normal losses don’t lead to production stoppages.

How Many Extra Components Should You Order?

The number of extra components required depends on the part type, cost, and total quantity needed. A general guideline for passive components is:

| Component Size | Need < 20 pcs | Need < 50 pcs | Need < 100 pcs |

|---|---|---|---|

| 01005 | Order 150+ | Order 200+ | Order 250+ |

| 0201 | Order 100+ | Order 150+ | Order 200-250+ |

| 0402 | Order 100+ | Order 150+ | Order 200-250+ |

| 0603 | Order 100+ | Order 150+ | Order 200-250+ |

| 0805 | Order 50+ | Order 100+ | Order 150+ |

| 1206 | Order 50+ | Order 100+ | Order 150+ |

For low-cost components like resistors and capacitors, ordering a few hundred extra costs just a few euros or dollars. The length of tape also matters—short strips are harder to load into feeders, so ordering a sufficient quantity ensures smooth machine operation.

For expensive ICs or specialty components:

- If fewer than 10 are needed, order at least 3 extra.

- If 50 or more are needed, add 5–10 extra.

- If over 100 are needed, an additional 10–20 pieces may be necessary.

These extra parts act as insurance, reducing the risk of delays due to minor losses. If the budget is tight and some parts are expensive, consulting your subcontractor is a good practice to determine if extra components are truly necessary.

Best Practices for Ordering Components

To avoid component shortages, follow these best practices:

- Consult your subcontractor before finalizing orders—different manufacturers have different minimum requirements.

- Order in reels or continuous strips rather than cut tape when possible. Short pieces of tape often cause feeding issues in SMT machines.

- Consider supplier lead times—if a component runs out during production, how quickly can replacements be sourced?

Conclusion

Ordering extra components may seem like an unnecessary expense, but in reality, it’s one of the simplest ways to prevent costly delays in PCB assembly. A small additional investment in passive components and critical ICs can ensure that manufacturing runs smoothly, without interruptions.

Next time you place an order for PCB assembly, don’t just think about the bare minimum—think ahead and give yourself a buffer. Your project schedule will thank you.