Kärynpoisto ja suojakäsineet elektroniikkateollisuudessa

Elektroniikkatuotanto voi näyttää siistiltä ja vaarattomalta, mutta todellisuudessa se sisältää useita terveysriskejä. Moni niistä jää huomaamatta, vaikka kyse on työntekijöiden turvallisuudesta. Tässä artikkelissa pureudutaan kahteen olennaiseen turvallisuustekijään: kärynpoistoon ja suojakäsineisiin.

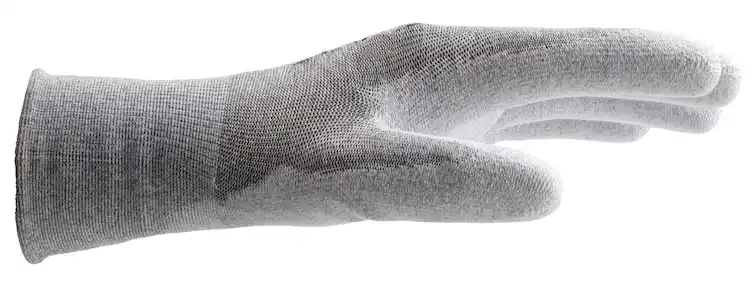

Suojakäsineet – mikä sopii mihinkin?

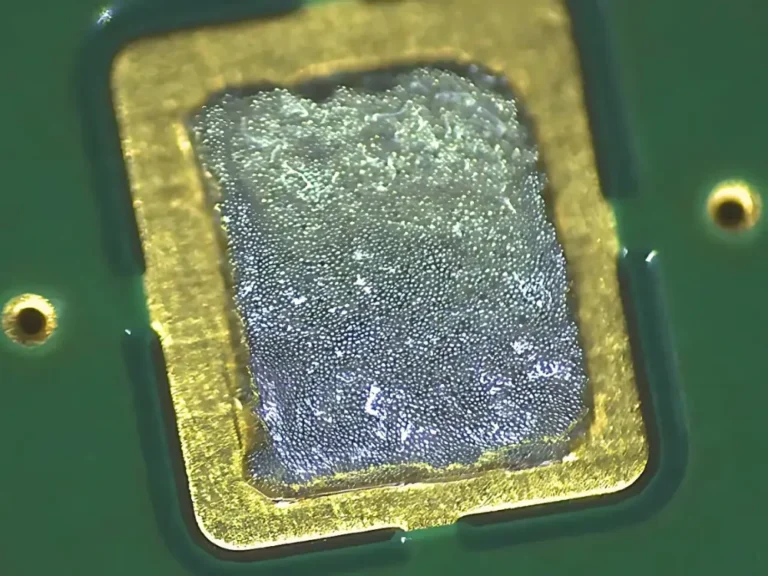

Käsineiden tärkein tehtävä ei aina ole suojata työntekijän ihoa, vaan suojata tuotetta työntekijältä. Erityisesti piirilevyjen kokoonpanossa on vältettävä sormenjälkiä ja ihon rasvaa, jotka voivat pilata herkät komponentit tai haitata suojapinnoitteiden, silikonien ja liimojen tarttuvuutta.

Case: Testissä kevyet sormenpäistä PU-pinnoitetut käsineet

Tässä esimerkissä testatut käsineet ovat EN 420 -standardin mukaisia kategoriassa I – eli ne suojaavat vain kevyiltä riskeiltä kuten naarmuilta. Ne eivät sovellu kemikaaleille, mekaaniselle rasitukselle tai biologiselle altistukselle.

Sormien päissä oleva polyuretaanipinnoite estää tehokkaasti silikonin läpipääsyn, vaikka käsine ei täytäkään EN 374 -kemikaalistandardia. Pinnoittamattomat kangasosat päästävät kuitenkin jonkin verran aineita läpi, joten kemikaalien käsittelyyn tarvitaan täysin pinnoitettu käsine.

👉 Tärkeä huomio: PU-pinnoite ei suojaa matalaviskoosisilta nesteiltä. Ne imeytyvät helposti materiaalin läpi.

Vaihtoehdot parempaan suojaan

Jos työssä tarvitaan enemmän suojaa, kannattaa kokeilla seuraavia:

- Nitrilikäsineet (ESD): Kestävät paremmin kemikaaleja, mutta voivat olla liian paksuja tarkkaan hienomekaaniseen työhön.

- Koko kämmenen alueelta PU-pinnoitetut ESD-käsineet: Antaa jonkin verran suojaa esimerkiksi paksuja silikoneja vastaan ja ohuen PU-pinnoitteen takia sormituntuma on hyvä hienomekaaniseen työhön.

Kemikaalien kanssa työskennellessä käsineiden on täytettävä EN 374 -standardi. Valitse käsineet aina käytettävän kemikaalin mukaan. Tutustu käytettävän kemikaalin käyttöturvallisuustiedotteeseen.

ESD-suojatut, kemikaalikestävät ja hienomekaaniseen työhön sopivat käsineet ovat harvinaisia. Tällä hetkellä ehkä parhain vaihtoehto on ohut kertakäyttöinen nitriilikäsine, joka tarjoaa molemmat ominaisuudet. Haittana tällä on se, ettei kertakäyttöinen nitriilikäsine ole hengittävä ja täytyy vaihtaa usein.

Kärynpoisto

Juotostyössä syntyy käryjä, jotka voivat pitkällä aikavälillä aiheuttaa vakavia terveysongelmia. Toimiva kohdepoisto on välttämätön, mutta sekään ei auta, jos kärynpoisto ei toimi oikein.

Ilmavirtauksen mittaaminen

Toimiva kärynpoisto vaatii ilmavirtauksen oikeaa mitoittamista. Testeissä käytettiin Alsident System 50 -kärynpoistojärjestelmää. Tulokset:

- Työpiste 1:

- 10 m/s (70 m³/h) – Hyvä ja suositusten mukainen ilmavirtaus.

- Työpiste 2:

- 15 m/s (106 m³/h) – Toimiva, mutta liian suuri ilmavirtaus aiheutti meluhaittoja.

💡 Alsident System 50 kärynpoistojärjestelmän suositukset ilmavirtaukselle:

✔️ Normaali: 65 m³/h

✔️ Minimi: 45 m³/h

✔️ Maksimi: 85 m³/h

Vinkki: Pidä kärynpoistoputken suutin alle 20 cm päässä käryn lähteestä. Muuten tehokkuus laskee nopeasti.

Suuttimen valinta

Suuttimen tyyppi vaikuttaa siihen, kuinka laajalta alueelta juotoskäryt saadaan talteen. Esimerkiksi:

- Ilman suutinta (vain putki) 85 m³/h ilmavirtauksella: Imualue ulottuu putken päästä keskeltä putkea noin 10-12 cm etäisyydelle.

- Tasohuuva 55 m³/h ilmavirtauksella: Saavutetaan saman kokoinen 10-12 cm imualue matalammalla ilmavirtauksella.

- Tasohuuva 85 m³/h ilmavirtauksella: Saavutetaan 17-20 cm kokoinen imualue.

Ilmavirtauksen lisääminen yli 85 m³/h ei juuri paranna imutehoa, mutta lisää melua ja kuluttaa kärynpoistojärjestelmän suodattimia nopeammin.

Eri töihin soveltuvia suuttimia :

Suora suutin: Tarkka, mutta vaatii siirtelyä käryn lähteen siirtyessä.

Leveä suutin: Sopii esimerkiksi piirikorttien juottamiseen eikä vaadi siirtelyä.

Tasohuuva: Sopii hyvin kemikaalikäryjen poistoon.

Kupumainen huuva: Sopii ylöspäin nousevien käryjen poistoon. Isokokoinen ja vaatii paljon tilaa.

Juotoskolviin asennettava imupilli: Poistaa juotoskäryn tarkasti suoraan juotosterän päästä. Vaatii säännöllistä puhdistusta ja saattaa tehdä juotoskolvista kömpelön.

Portable Fume Extractors: A Practical Solution for Flexible Workspaces

In many electronics manufacturing environments, installing a fixed exhaust system to vent fumes outside the building is not always an option. This may be due to building restrictions, temporary workspaces, or cost constraints. In such cases, portable fume extractors provide an effective alternative.

These standalone units are equipped with high-performance HEPA and chemical filters, capable of capturing hazardous fumes and particles directly at the source. Instead of relying on external ventilation, the extractors purify the air and recirculate it back into the workspace, ensuring a cleaner and safer environment.

Siirrettävä kärynpoistojärjestelmä

Aina ei ole mahdollista rakentaa kiinteää kärynpoistojärjestelmää. Esimerkiksi vuokratiloissa, tilapäisissä työpisteissä tai usein muuttuvassa layoutissa siirrettävä kärynpoisto on käytännöllinen vaihtoehto. Muista kuitenkin vaihtaa suodattimet säännöllisesti. Tukkeutunut suodatin heikentää sekä imutehoa että suodatustehoa.

Miten testata kärynpoiston tehokkuutta?

Savukynä (esim. Dräger Smoke Pen) näyttää konkreettisesti, miten hyvin käryt kerätään talteen. Sitä voi käyttää myös kärynpoiston suuttimen sijainnin säätämiseen.

Juotoskäryjen mittaaminen on haastavaa

Juotoskäryistä syntyvien partikkeleiden (10–500 nm) on haastavaa ja vaatii erityiset tähän kykenevät laitteet kuten esimerkiksi Testo DiSCmini. Tällaisten laitteiden hinnat lähtevät helposti 2000 eurosta ylöspäin ja kertaluonteisen mittauksen takia hankinta voi olla vaikeaa perustella.